Gọi cho chúng tôi ngay

+86 18706432618

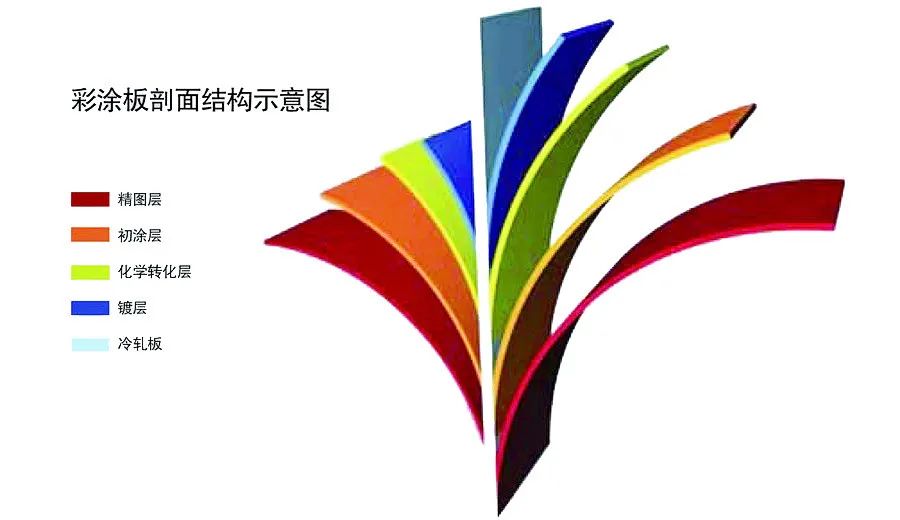

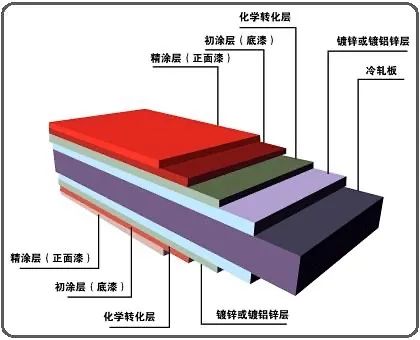

Tôn mạ màu là tôn được phủ một lớp sơn màu hoặc màng màu lên bề mặt của vật liệu nền như tôn mạ kẽm, tôn galvalume hoặc tôn cán nguội. Một mặt, nó có thể bảo vệ kim loại nền, mặt khác, nó có thể đóng vai trò trang trí. Có ba loại lớp phủ: lớp phủ hữu cơ, lớp phủ vô cơ và lớp phủ tổng hợp, loại nào phát triển nhanh nhất.

Giới thiệu

1936

Bảng phủ màu ra đời tại Hoa Kỳ.

Ban đầu, nó được sử dụng trong xây dựng như rèm che và tấm chắn mưa. Ngay từ đầu, nguyên liệu thô là những tấm đơn hoặc cuộn thép tráng phủ liên tục rộng 2 inch, do Amco Steel Corp và Heart Engineering sản xuất.

1949

Cải tiến quy trình tại Hoa Kỳ

và

S

1954

Tấm phủ màu được sản xuất tại Nhật Bản

1961

Anh cũng bắt đầu sản xuất các tấm phủ màu

Sau đó, các nước phát triển như Đức và Thụy Điển cũng bắt đầu sản xuất hàng loạt tấm thép phủ màu, chủ yếu phục vụ mục đích xây dựng.

1969

Vì Nhật Bản nằm trong vùng động đất nên các tòa nhà thép mạ màu nhẹ, chống động đất được ưa chuộng hơn. Tỷ lệ thép mạ màu sử dụng trong các tòa nhà chiếm khoảng 76% lượng tiêu thụ trong nước và sản lượng tấm thép mạ màu tăng trưởng đều đặn.

Những năm 1970

Các nước Châu Á bắt đầu sản xuất

Một số nước Châu Á: Hàn Quốc, Philippines và Đài Loan đã bắt đầu xây dựng dây chuyền sản xuất thép tấm mạ màu liên tục.

Những năm 1980

Trung Quốc giới thiệu thiết bị sản xuất

Vào những năm 1980, các nền kinh tế mới nổi mà đại diện là Trung Quốc đã bắt đầu nghiên cứu và phát triển hoặc giới thiệu các thiết bị sản xuất thép mạ màu.

Những năm 1990

Ấn Độ và các nước Tây Á cũng bắt đầu sản xuất tấm thép phủ màu

Hiện nay

Cuộc sống không thể tách rời khỏi những tấm bảng màu

Là loại vật liệu xây dựng mới, tấm thép phủ màu có đặc điểm là tuổi thọ cao, tiết kiệm đất và có thể tái chế, được ứng dụng rộng rãi trong các công trình công cộng và nhà máy công nghiệp.

01

Theo phân loại vật liệu nền dùng làm thép tấm phủ hữu cơ là: tôn cán nguội, tôn mạ kẽm nhúng nóng, tôn mạ kẽm điện phân, tôn hợp kim, tôn galvalume, tôn hợp kim mạ điện phân, tôn mạ thiếc, tôn mạ crom và tôn nhôm.

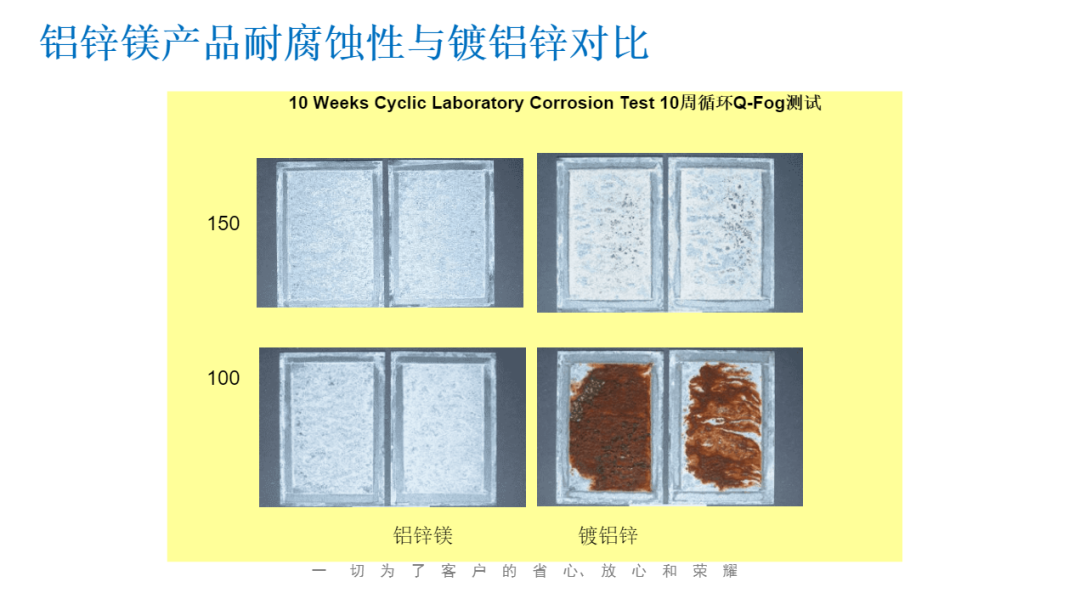

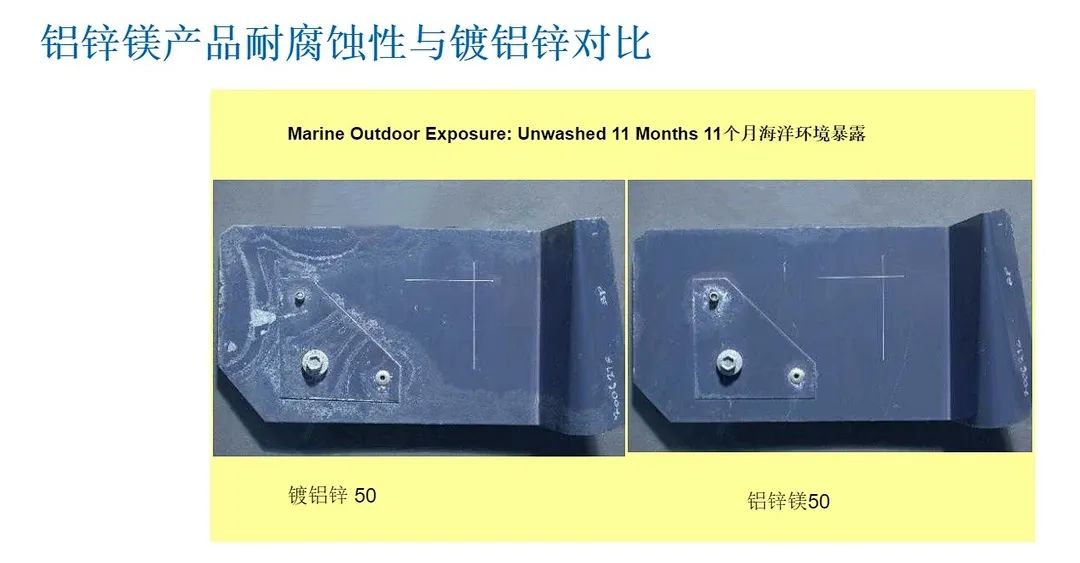

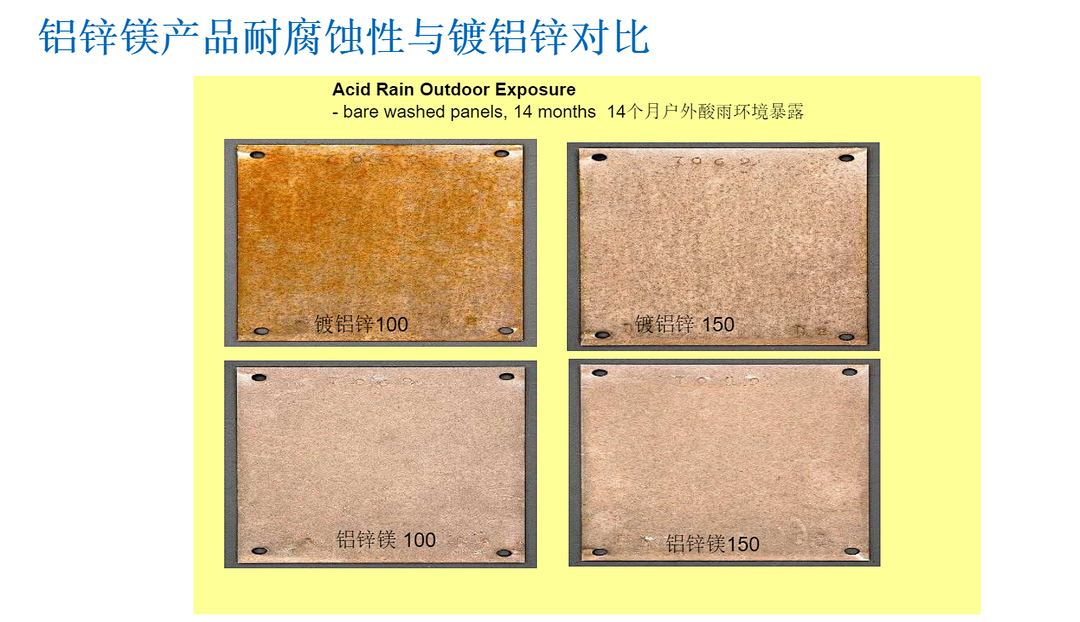

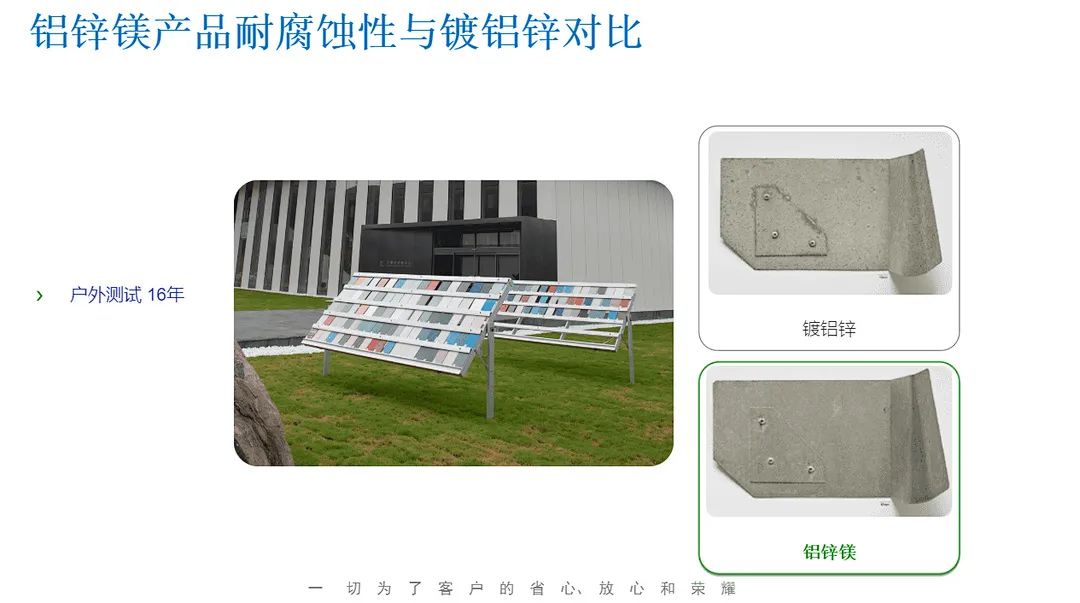

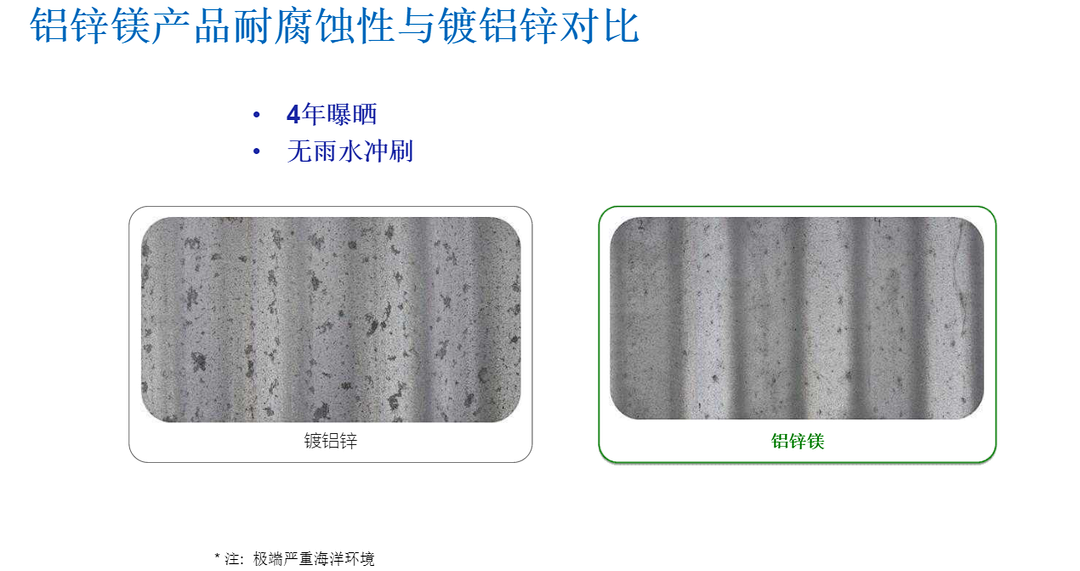

Trong những năm gần đây, với sự phổ biến và ứng dụng của các nguồn năng lượng mới như năng lượng mặt trời, năng lượng gió và yêu cầu bảo vệ môi trường ngày càng nghiêm ngặt do môi trường ăn mòn khắc nghiệt, các kim loại hợp kim như hợp kim nhôm-kẽm và hợp kim kẽm-nhôm-magiê đã lần lượt được sản xuất nhằm mục đích tăng khả năng chống ăn mòn của lớp kim loại.

02

Shinmade có kế hoạch triển khai dự án mới về tôn mạ kẽm chống ăn mòn cao nhôm-kẽm-magiê. Tôn mạ kẽm AZM là thế hệ tôn mạ kẽm chống ăn mòn cao mới. Hàm lượng thành phần kim loại trong lớp mạ là: 53% nhôm, 43% kẽm, 2% magiê, 1,5% silic và các thành phần khác. Là vật liệu chính của tấm lợp và mặt tiền của hệ thống kết cấu thép, sản phẩm thép AZM thay thế thép mạ kẽm thế hệ thứ nhất và thứ hai vì hiệu suất chống ăn mòn và tuổi thọ cao.

Lớp phủ AZM có đặc tính chống ăn mòn. Các thành phần kim loại trong lớp phủ hợp kim hoạt động cùng nhau để giảm tỷ lệ tiêu thụ lớp phủ bề mặt. Đồng thời, khả năng chống ăn mòn của phần cắt của thép phủ cũng được cải thiện. Trong hầu hết các trường hợp, hiệu suất của nó tốt hơn so với tấm thép galvalume nếu có cùng lượng lớp phủ.

Kẽm trong lớp phủ hợp kim cung cấp khả năng bảo vệ hy sinh, và nhôm cung cấp khả năng bảo vệ thụ động. Vật liệu magiê kích hoạt lớp phủ, giảm tốc độ tiêu thụ của lớp phủ và tạo thành lớp bảo vệ cách điện trên lưỡi cắt và mặt cắt ngang. Nguyên tố kẽm cũng bảo vệ các lớp phủ kim loại, giúp cải thiện hiệu quả khả năng chống ăn mòn của các sản phẩm thép được phủ.

Tuổi thọ của tấm thép nhôm-kẽm-magiê trong môi trường chung là hơn 30 năm.

03

Sự phát triển của nền văn minh nhân loại đặt ra những yêu cầu mới cho ngành xây dựng. Chỉ bằng cách theo đuổi kiến trúc và cái đẹp liên tục, chúng ta mới có thể làm cho các sản phẩm sơn phủ màu trở nên hoàn hảo.

Dự án tôn mạ nhôm-kẽm-magiê chống ăn mòn cao Shinmade hiện đang được triển khai. Sau hơn 40 năm phát triển, Shinmade đã thành lập Viện nghiên cứu riêng về thép cán nguội, thép mạ và các sản phẩm thép xây dựng. Bên cạnh đó, công ty cũng thành lập một nhóm chuyên gia cao cấp để thúc đẩy sự hợp tác sản xuất, học tập và nghiên cứu cho các sản phẩm sơn phủ.

Về nghiên cứu màu sắc của tấm phủ, chúng tôi đã xây dựng trung tâm phối màu với các thợ sơn hàng đầu thế giới để tạo ra hệ thống quản lý màu chuyên nghiệp, cung cấp cho khách hàng các sản phẩm sơn tùy chỉnh và chức năng mà họ có thể tự chọn màu.

Quét vào Wechat