Call Us Now

+86 18706432618

Galvalume is a coating consisting of zinc, aluminium and silicon that is used to protect the metal from oxidation. And it would be less likely to rust than normal galvanized steel. These products are mainly used in the outdoor metal facades, panels and roofing.

Product origin:

China| Product Specifications | |||

|

Plating composition |

Plating thickness |

Product thickness |

Product width |

|

55% aluminum 43.5% zinc 1.5% silicon |

AZ30-AZ220 |

0.15–1.60mm |

700–1260mm |

| Product Warranty | ||

|

The amount of aluminum-zinc plating AZ150

Warranty period 20 years |

The amount of aluminum-zinc plating AZ180

Warranty period 25 years |

The amount of aluminum-zinc plating AZ200+

Warranty period 30 years |

Corrosion resistance mechanism

Corrosion resistance mechanism Corrosion resistance

Corrosion resistance

Product Advantages

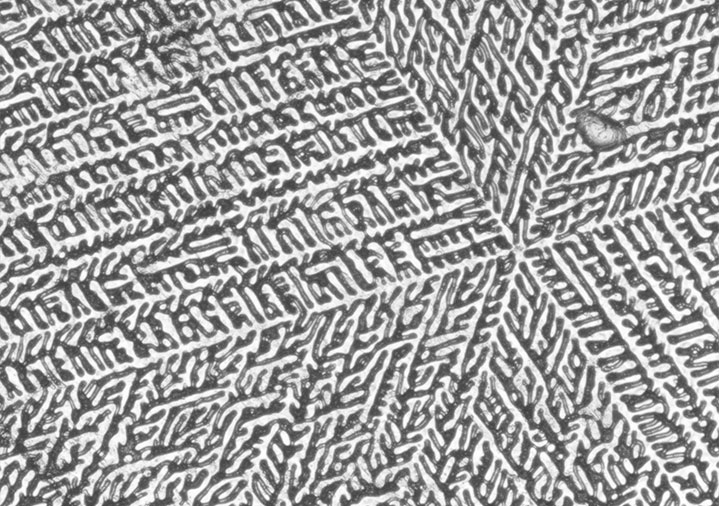

Small dendrites space distance

Dendrite spacing is an important factor in measuring the corrosion-resistance of the coated products. The smaller the dendrite spacing, the better the corrosion resistance of the coating layers. If the dendrite spacing of galvalume steel is greater than 20μm, the corrosion resistance of the product is poor.

With unique formula of the coating and control of coating thickness, the dendrite spacing of Shinmade galvalume steel is 10-15μm under electron microscopy, and the corrosion resistance of the product is excellent.

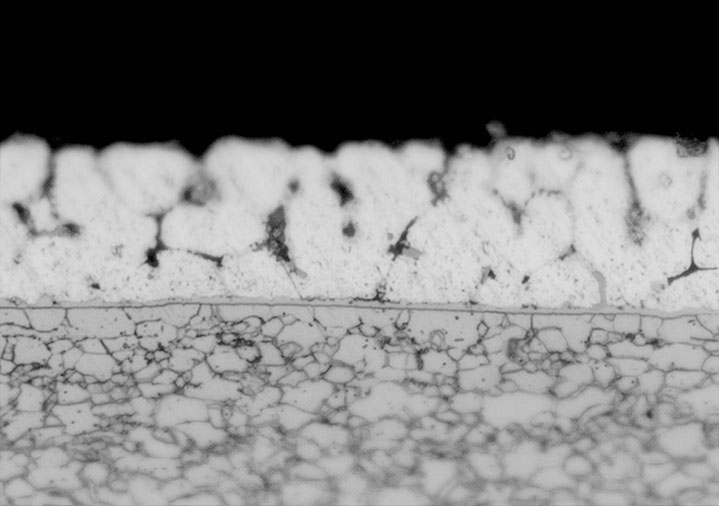

Ideal coating structure

The coating structure of Shinmade’s products is a staggered skeleton, which has good density and can prevent the intrusion of rainwater and other corrosive media, and that is why the product has good corrosion resistance. If the coating structure is bamboo-like, which means the coating layer is not dense enough and the corrosion resistance can be poor.

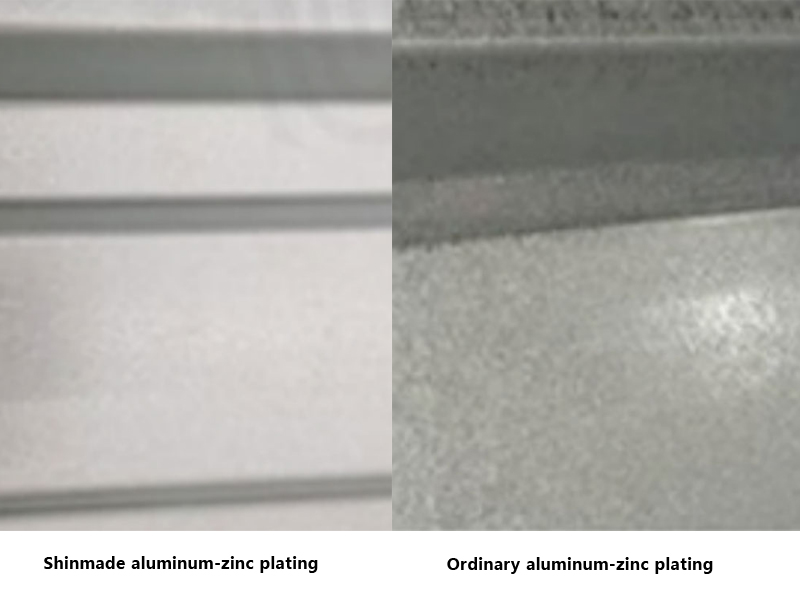

Small-sized and uniform spangle

The stability of crystallization determines the size and uniformity of spangles. The spangles are precisely controlled under the combined effects of the steel strip temperature, zinc liquid temperature, surface roughness, post-plating cooling, and special coating formula. The diameter of the spangle of Shinmade's galvalume is controlled between 0.5-3mm, which means the spangles are small-sized and uniform, and the appearance effect is more stable.

Chromate/Passivation+AFP

We adopt double-coating and baking process for post-treatment, which means we first to passivate, dry and cool the sheets, next to apply AFP coating on the sheets and dry and cool. The AFP film is thicker and cured better, so the processing lubricity is relatively better.

Aluminum-zinc sheet refers to the steel plate plating on the basis of zinc added aluminum (passivation protection), the general composition is 55% aluminum, 43.5% zinc, 1.5% silicon, with excellent atmospheric corrosion resistance, corrosion resistance is 2-4 times that of galvanized sheet, but also has the high temperature corrosion resistance of aluminum plate, smooth surface, good appearance.

Uses: building roofs, walls, electrical cabinets, home appliances, automobiles, color-coated substrates, etc.

Why Choose Shandong Shinmade?

The predecessor of Shandong Shinmade Material Tech Co. started in 1978 and has a history of 47 years. Shinmade is a modern steel enterprise integrating science research, production, trade and warehousing. It focuses on the production of PPGL steel coil, galvalume steel coil, hot-dip aluminum-zinc-magnesium alloy coated steel, cold rolled steel coils.

Shinmade's Certificate

Q: Can we visit your factory?

Warmly welcome. Once we have your schedule, we will arrange a professional sales team to follow up with you.

Q: Can you provide samples?

A: Yes, for regular size samples it is free.

Q: Why choose our company?

A: We have more than forty years of professional experience in this industry.

Scan To Wechat